Lasers for Two-Photon Polymerization

FemtoFiber Technology for Two-Photon Polymerization

- Microfabrication with two-photon polymerization

- High penetration depth

- Fast writing process

- Average power 50 mW .. 1.5 W (depending on processing speed)

- Pulse width typically 100 .. 200 fs

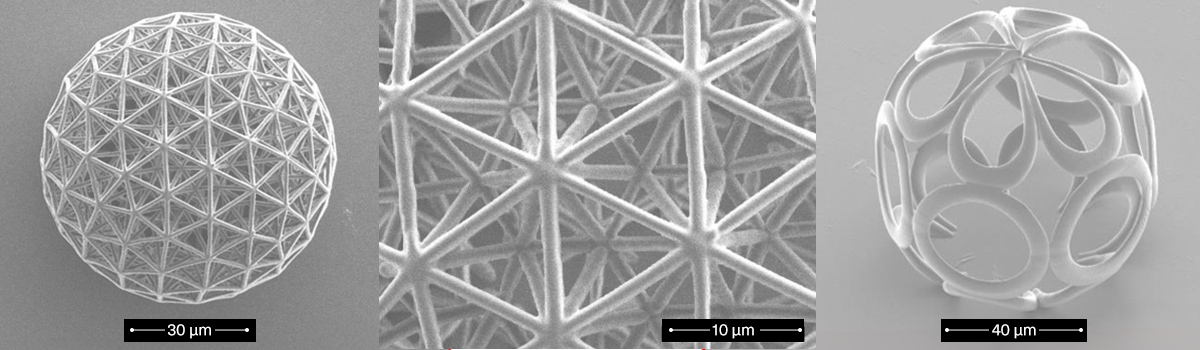

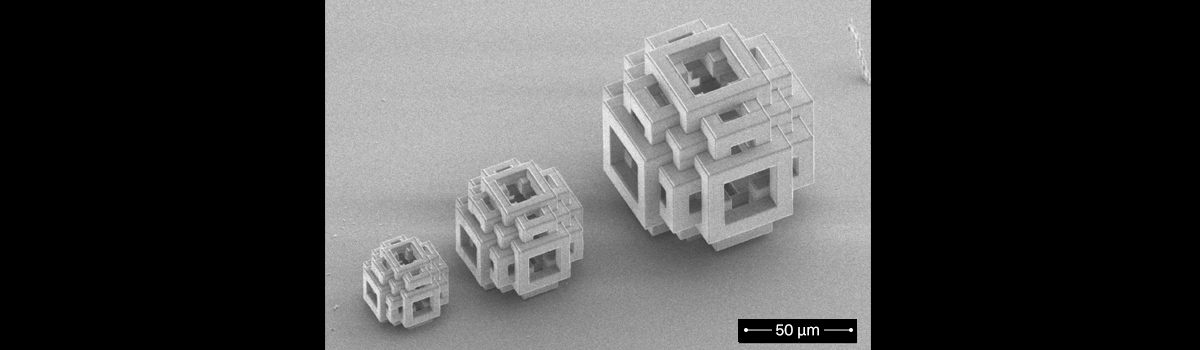

Lithography on the sub-micrometer scale has long been limited to planar objects. In 1997, the emergence of two-photon polymerization enabled three-dimensional fabrication in the 100 nm regime. Since then, an increasing demand in miniaturized devices like nanotubes or scaffolds for micro- and nanotechnologies lead to a fast development of lithographic techniques. Allowing for fabrication of arbitrary 3D structures with resolution beyond the diffraction limit of light, two-photon polymerization (TPP) has the potential to play a key role in laser lithography.

Process of Two-Photon Polymerization

Two-photon polymerization as a direct laser writing technique allows for creating complex three-dimensional structures down to feature sizes on the order of 100 nm. Key elements of two-photon polymerization are lasers providing femtosecond pulses, suitable photosensitive materials (photoresists), a precise positioning stage and a computer to control the procedure.

Two-photon polymerization is a non-linear optical process based on the simultaneous absorption of two photons in a photosensitive material (photoresist). This process changes the photosensitive material, i.e. it leads to a polymerization by activating so-called photo-initiators in the resist. These turn into radicals that polymerize the resist locally. In a subsequent step, the non-polymerized photoresist is washed out to uncover the structure. The material of the structures is not restricted to just polymers but can be converted for example into silicon via a secondary chemical process.

Advantages of Two-Photon Polymerization

Two-photon absorption requires high intensities - these are provided by a tightly focused femtosecond laser beam. As two-photon absorption is proportional to the square of the intensity, it only takes place in the focus providing high spatial resolution. Accordingly, the resist polymerizes only in the ellipsoidal focus, termed “voxel” (abbr. for volume pixel). Scanning the laser through the resist in all three dimensions “writes” the desired structure voxel by voxel. During two-photon polymerization the surrounding oxygen quenches the radicals to a certain extent. This results in feature sizes down to ~100 nm. Another advantage of two-photon polymerization is that many polymers have next-to-none linear absorption in the near-infrared, allowing the laser to penetrate deeply into the material. These two aspects allow creating nano-structures that are otherwise not possible to produce.

Computer-aided exposure of a multitude of photoresists as well as established 3D casting techniques make direct laser writing an indispensable tool for a large variety of applications in life sciences (e.g. extra cellular matrices, lab-on-a-chip,…), (opto-)electronics or photonics (e.g. photonic crystals).

TOPTICA's added value

For two-photon polymerization, typically lasers at 780 nm with 100 .. 200 fs pulse width and 50 .. 500 mW average power are employed. Fiber lasers are an ideal choice because of their compactness, reliability and cost effectiveness. The higher the pulse energy, the faster and deeper into the resist can be written. TOPTICA’s fiber lasers offers a variety of suitable lasers: FemtoFiber smart 780 PT (50 mW/< 100 fs), FemtoFiber smart 780 (120 mW/< 100 fs) and FemtoFiber ultra 780 (up to 1.5 W/< 150 fs).