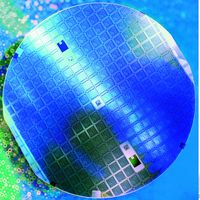

Diode Lasers for Microlithography

Diode lasers improve microlithography

Moore’s law is king: Striving for ever smaller structures is the clear target of microlithography. In modern microlithographic systems compact violet and UV diode lasers have taken the place of bulky gas lasers or HeCd lasers already. The superior performance of diode lasers enable improved up-times, lower cost of ownership and qualities of written features, which haven’t been imagined until recently. TOPTICA is proud to offer the most advanced diode lasers in perfect alignment with the high demands in fields like direct mask writing.

The advantages over gas lasers are manifold: Gas lasers always operate in cw mode and pulse generation has to be performed by external modulators. Diode lasers, however, can be pulsed at high frequencies. Different levels of imaging, so called gray-scaling, is accomplished simply by pulse width modulation.

Typical run times of blue gas lasers are a few thousand hours. Violet diode lasers exceed that level by a factor of two or three, improving the uptime of your system. Moreover, TOPTICA offers optimal single-mode diode lasers that are engineered to fulfill even the most demanding tasks.

-

Related Products

-

Literature

Application Note: Resource-efficient generation of large-area micro and nanostructures, Photonics Views, February / March 2023